The process of manufacturing plated jewellery is similar to that of fine jewellery. Before ending the manufacturing process, an additional layer of plating is added to the base metal to give it the desired color and finish.

The following steps are the jewellery manufacturing process for ZHULIAN plated jewellery:

1. Design and Conceptualization

The jewellery design process begins with conceptualizing the desired design. This involves sketching the jewellery piece to be manufactured, with consideration of aesthetics, functionality, user desires and needs that are deeply reflected through the current market and fashion trends.

Besides design, the next important decision-making is to select the material used, which includes the base metal selection and plating metal selection (if applicable).

During base metal selection, the appropriate base metal is chosen based on the design and desired characteristics of the final piece. Common base metals used include silver, copper, brass or other alloys. The plating metal such as gold, rhodium, or rose gold, is typically chosen based on aesthetic preferences and market demand.

2. Model Making

Once the design is finalized, a model of the jewellery is created using 3D printing technology. If the model made is accurate and adheres to the original design specifications, the model is then moved to the mold-making stage.

3. Molding

The rubber mold is then created to assist in replicating the model into multiple pieces of the same designed jewellery.

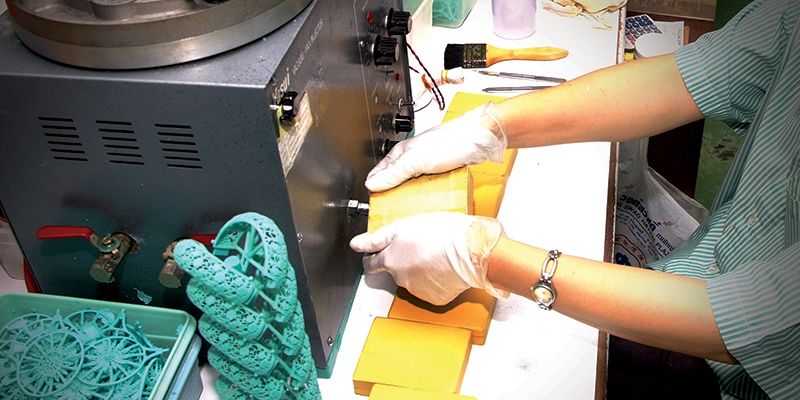

4. Waxing

The process of waxing involves the pressure injection of wax into the mold cavity to create wax models that will further be used for casting in the desired metal. Each wax piece is individually soldered on a wax stem, forming a wax tree ready for mass production.

5. Casting

The wax tree is placed in a cylindrical steel flask and further filled with slurry of chemical powder, which hardens to form a mold around the wax. The flask is then placed in the electric furnace and heated to a high temperature to form a cast as the wax melts, leaving behind a hollow cavity.

The chosen molten metal (e.g., brass, gold, silver or other alloys) is poured into the cavity to fill it and take the shape of the jewellery piece. After that, the molten metal in the flask is allowed to cool and demolish the cask to reveal the jewellery.

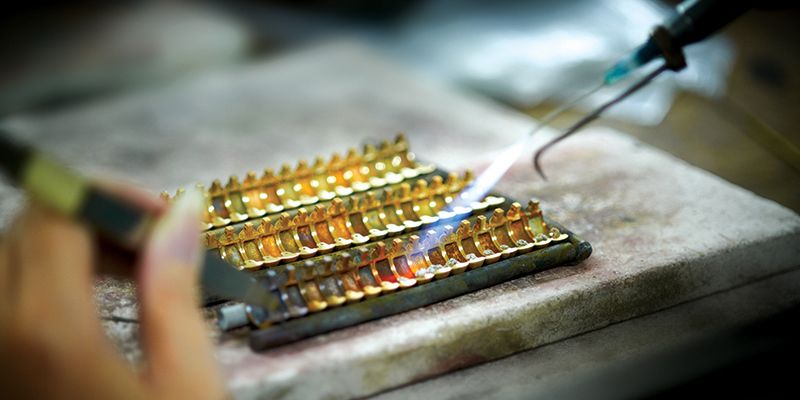

6. Soldering, Assembly and Pre-Polishing

The jewellery is removed from the stem and goes through the process of grinding to smoothen the surface of the jewellery. Next, soldering is taken place to join pieces of metal together using a filler metal. This is where earring posts are added to earrings or connecting a bail onto the pendant.

Once the soldering step is completed, the jewelry is ready to move to the assembly stage by assembling various parts of the jewellery. It could be attaching drops to the pendant or earrings.

Lastly, the jewellery goes through a process of pre-polishing to remove any rough edges or minor surface imperfections, ensuring a smooth finish before the gemstone is set.

7. Engraving

The jewellery may go through the process of engraving. The engraved design could be some patterns or textures on the metal surface as the finishing touches to enhance the jewelry piece.

8. Stone Setting

If the jewellery includes gemstones, our experienced craftsmen will carefully set the sparkling stones into the mount securely.

9. Polishing

The jewellery undergoes the final stage of polishing and buffing the edges to bring out the smooth and high lustrous shine finish.

10. Plating

The one last step for plated jewellery is the process of applying a layer of plating metal onto the jewellery using the electroplating method after quality check. In Zhulian, we have plated jewellery offers in either gold plated, rhodium plated or rose gold plated.

11. Quality Control

At this point, the complete plated jewellery goes through quality control checks and inspection to ensure that the jewellery manufactured adheres to the quality guidelines, meets the standard requirements and is free from any defect.

12. Packaging

Now it is time to package and is ready to ship to our customers to excite their day with exclusive jewellery.

Our 30 years of experience craftsmen have been making jewellery for thousands of satisfied customers who are just like you. You have to try it out yourself to know why our customers have been wearing our jewellery – Find your new favourite with Zhulian Jewellery.